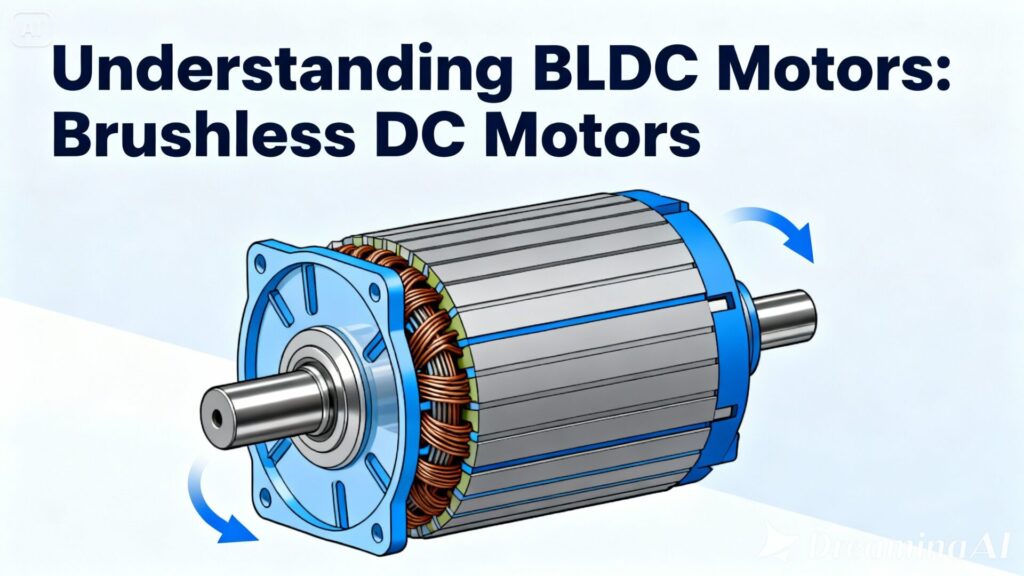

Understanding BLDC Motors

Electric motors are fundamental components of modern industry and everyday life. From automobiles and household appliances to industrial robots and manufacturing systems, they are everywhere. Among these, BLDC motors (Brushless DC motors) stand out due to their high efficiency, long lifespan, and low maintenance requirements.

Thanks to their brushless design, BLDC motors minimize mechanical wear and significantly extend service life. This is why they are widely used in electric vehicles, industrial automation, drones, medical devices, and many other applications. But what exactly is a BLDC motor, how does it work, what are its advantages, and where is it applied? Additionally, which BLDC drivers are commonly available on the market?

What Is a BLDC Motor?

A BLDC motor is a brushless direct current motor, unlike traditional DC motors, it has no brushes. This brushless design reduces mechanical wear and lowers maintenance requirements.

The motor consists mainly of two components:

- Stator: Stationary, with permanent magnets, interacting with electromagnetic fields.

- Rotor: Electromagnetic coils controlled by electronic drivers generate rotation.

Its operation converts electrical energy into magnetic energy through the driver. The absence of brushes reduces friction, ensures quiet operation, and increases energy efficiency.

Advantages of BLDC Motors

BLDC motors offer numerous advantages over conventional motors:

- Long lifespan and low maintenance: Brushless design minimizes wear.

- High efficiency: Low energy losses and high performance.

- Quiet operation: Minimal noise, ideal for household and medical equipment.

- Precise speed and torque control: Achievable through electronic drivers, essential in automation and robotics.

- Compact and lightweight: Suitable for mobile or space-constrained applications.

- Efficient thermal management: Heat is distributed evenly due to the brushless design.

- Energy savings: Optimized power consumption, especially in high-performance applications.

Applications of BLDC Motors

BLDC motors are used across many industries:

- Automotive: Electric and hybrid vehicles, air conditioning systems, pumps, windows, wipers.

- Industrial automation: CNC machines, robotic arms, conveyors, packaging machinery, production lines.

- Drones and robotics: Lightweight yet high-torque motors for drones, robots, and portable devices.

- Household appliances: Vacuums, fans, air conditioners, and small motorized devices.

- Medical devices: Quiet, reliable operation in ventilators, pumps, surgical robots, and precision equipment.

- Renewable energy: Motors or generators in solar and wind energy systems.

BLDC Motor Drivers and Control

Brushless motors cannot run directly on power. The stator’s magnetic fields must switch at precise times depending on rotor position. This is managed by BLDC drivers.

Popular BLDC drivers on the market include:

- STMicroelectronics L6234 / L6235: Small to medium motors, e.g., fans, pumps, robotics.

- Infineon TLE series: Automotive and industrial applications with compact design and protection features.

- Microchip MCP / dsPIC drivers: Programmable for precise speed and position control.

- Texas Instruments DRV series: Widely used in industrial automation and robotics.

Choosing the right driver directly affects performance, efficiency, and motor lifespan. Wrong selection can lead to overheating, power loss, or unexpected failures.

Installation and Integration

For optimal operation, BLDC motor performance depends not only on driver choice but also on system integration:

- Sensor-based control: Rotor position sensors enable precise operation.

- Sensorless control: Software algorithms estimate rotor position for control.

- IoT and HMI integration: Real-time monitoring of motor status and performance for automation and remote maintenance.

- Thermal management: Sensors and cooling ensure safe continuous operation.

Conclusion

BLDC motors play a key role in modern technology thanks to their brushless construction, electronic control, and high efficiency. They operate quietly, reliably, and with minimal maintenance, finding wide applications—from automotive and industrial automation to robotics and medical devices.

Choosing the right motor and driver maximizes system performance and reliability, reduces mechanical wear and maintenance costs, and provides high precision, low noise, and energy efficiency. With advanced drivers and IoT/HMI integration, motors can be monitored and optimized in real time. BLDC motors are among the most reliable and efficient solutions for modern motion control applications.

🔗 Get in touch with us :

Phone/WhatsApp: +41 76 212 8248

✉️ E-Mail: info@revantechnology.com

For detailed information about our services in electronics development & PCB design:

Revan Technology – Your partner for professional electronics and PCB development

Discover our recent work:

Revan Technology – Our Projects