İntroduction

PCB assembly is the process of placing and soldering all electronic components on a printed circuit board (PCB) according to a specific plan. It is one of the most critical steps in electronics manufacturing, as it directly determines whether a device will function correctly.

Why is PCB Assembly Needed?

The goal of assembly is to make a designed circuit operational. The structure defined in the schematic is transferred onto the PCB and populated with components such as resistors, capacitors, microcontrollers, diodes, or integrated circuits (ICs). After assembly, the circuit is electrically functional.

How Does the PCB Assembly Process Work?

Assembly can be done manually or fully automatically. Professional manufacturers mostly use SMT production lines today for fast, precise, and low-error assembly. Smaller quantities are still often hand-assembled.

Key Steps:

- Material Preparation

All required components are procured, sorted, and assigned according to the production plan. Even a single incorrectly placed resistor can compromise the entire PCB. - Applying Solder Paste

In SMT assembly, solder paste is applied to the PCB pads. It holds the components in place and ensures a permanent connection during soldering. - Component Placement (Pick & Place)

Automated machines place components quickly and accurately. In manual assembly, technicians use tweezers or vacuum tools. - Reflow Soldering

The populated board passes through a reflow oven. The solder paste melts, forming a solid connection between the component pins and PCB traces, then cools down. - THT Assembly (Through-Hole Technology)

Larger or mechanically robust components (connectors, relays, transformers) are inserted through holes and usually soldered via wave soldering. - Optical and Electrical Testing

After soldering, the PCB undergoes Automatic Optical Inspection (AOI) and functional or in-circuit tests to detect solder defects, short circuits, or misplaced components. - Cleaning & Quality Control

Residual flux is removed, and the PCB goes through final quality checks before it is ready for use.

Types of PCB Assembly

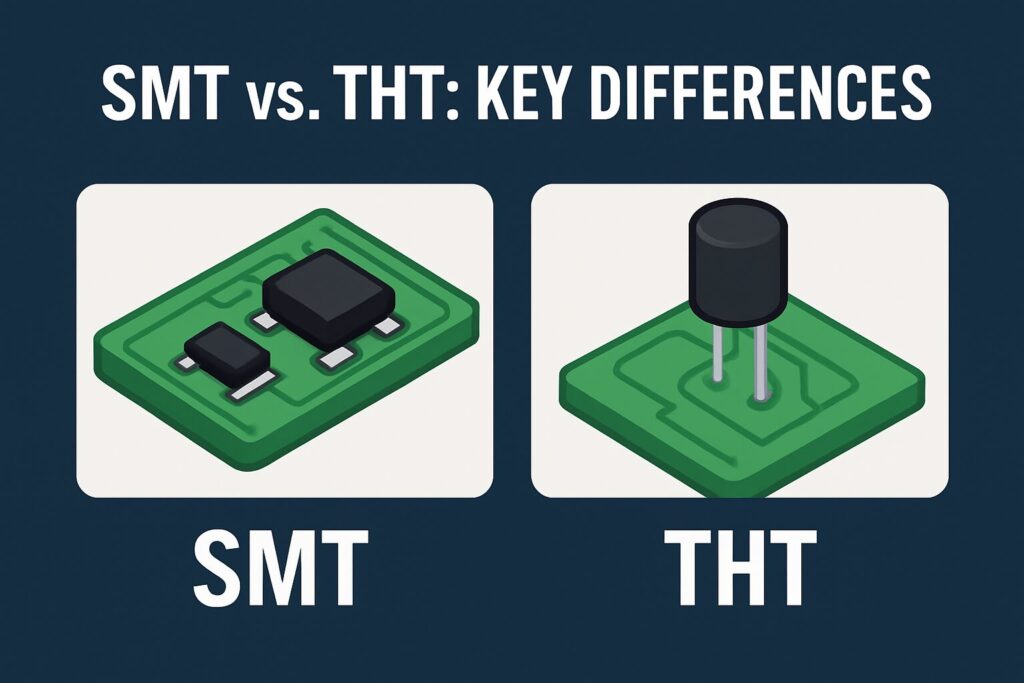

SMT (Surface Mount Technology)

- Components are mounted directly on the PCB surface.

- Advantages: compact, fast, cost-effective, easily automated.

THT (Through-Hole Technology)

- Components are inserted through holes and soldered on the reverse side.

- Advantages: high mechanical stability, ideal for high currents and rugged applications.

Many modern boards use a combination of both methods, known as hybrid PCBs.

Important Quality Factors in PCB Assembly

- Components must be mounted in the correct orientation.

- Polarity-sensitive components (diodes, electrolytic capacitors) must not be reversed.

- The correct amount of solder paste must be applied.

- The reflow oven temperature profile must be accurate.

- AOI inspection should always be part of the process.

- ESD protection is mandatory.

What to Consider When Outsourcing PCB Assembly (PCBA)

When outsourcing PCB assembly, consider:

- The manufacturer has an SMT line and reflow oven.

- ESD-protected work areas are available.

- Certifications such as ISO or IPC are present.

- AOI and functional testing are offered.

- Prototype production (small quantities) is possible.

These factors directly affect the quality, cost, and reliability of the final product.

Conclusion

PCB assembly (PCBA) is the critical step where an electronic circuit becomes reality. It combines precise machine work with careful quality control, ensuring every component is correctly placed and reliably soldered. Only with this precision can the intended functionality of the circuit be guaranteed.

A well-assembled PCB extends device lifespan, reduces failure and defect rates, and ensures that the final product is both technically reliable and visually professional. Careful assembly also enables more efficient production, minimizes rework, and simplifies later maintenance.

🔗 Get in touch with us :

Phone/WhatsApp: +41 76 212 8248

✉️ E-Mail: info@revantechnology.com

For detailed information about our services in electronics development & PCB design:

Revan Technology – Your partner for professional electronics and PCB development

Discover our recent work:

Revan Technology – Our Projects