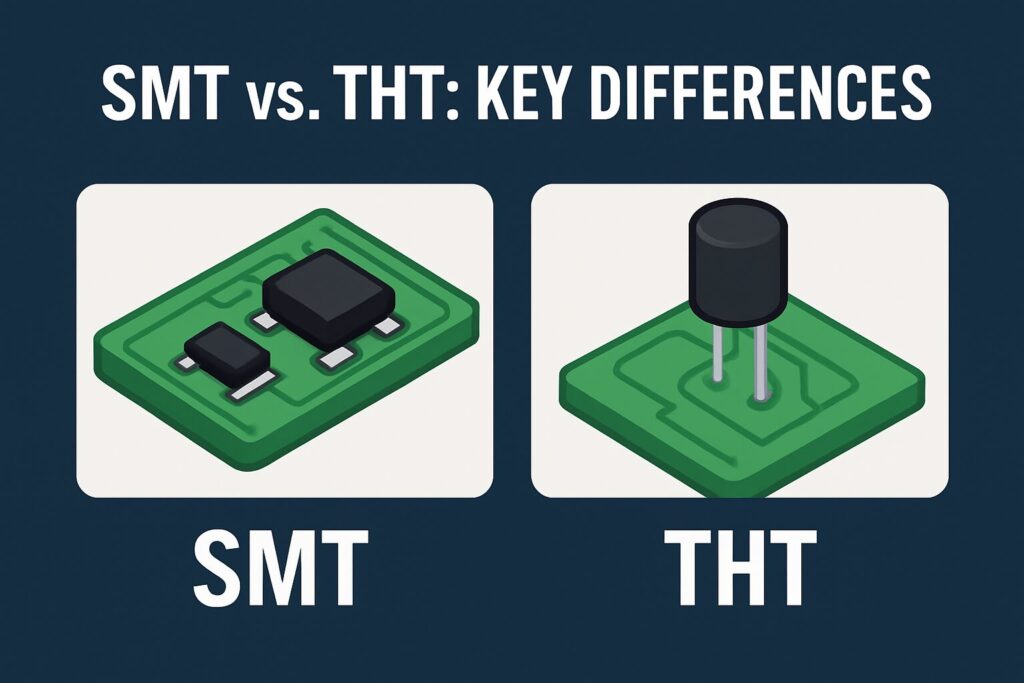

SMT vs. THT

When designing and manufacturing printed circuit boards (PCBs), you’ll often encounter the terms SMT and THT. Both methods are used to mount electronic components on a PCB, but they differ significantly in how they work, their advantages, and their typical applications. This article explains SMT and THT, highlights the differences, and provides guidance on when to use each method.

What Is SMT (Surface Mount Technology)?

SMT, or surface mount technology, allows components to be placed directly on the surface of the PCB. Components are not inserted through holes but mounted on solder pads and soldered in place. This technique enables a much more compact PCB design, as components can be smaller and placed closer together.

Advantages of SMT:

- Compact design: Small components allow for space-saving modern devices.

- Automation-friendly: Ideal for automated assembly, increasing production speed and reducing errors.

- Cost-effective: Automation and smaller components lower manufacturing costs.

- High-frequency performance: Short connections improve performance in high-frequency circuits.

- Flexible production: Easily adapted for large-scale manufacturing.

Disadvantages of SMT:

- Repairs and replacements can be more complex, requiring specialized tools.

- Mechanical durability is lower; components are sensitive to vibration, shocks, or temperature changes.

- Not always ideal for high-current or high-voltage applications.

What Is THT (Through-Hole Technology)?

THT, or through-hole technology, involves inserting component leads through holes in the PCB and soldering them on the opposite side. This older method is still preferred in applications requiring strong mechanical stability.

Advantages of THT:

- Mechanical stability: Components are firmly seated, ideal for heavy parts or vibration-prone environments.

- Easy repair and testing: Components can be easily removed or replaced, useful for prototypes.

- High-current and high-voltage applications: Offers more safety and reliability.

- Long-term durability: Less prone to material fatigue in demanding industrial conditions.

Disadvantages of THT:

- Requires more PCB space, limiting miniaturization.

- Typically manual or semi-automated assembly, increasing production cost.

- Harder to achieve high production speed.

Main Differences Between SMT and THT

| Feature | SMT | THT |

|---|---|---|

| Mounting method | Soldered on the surface | Inserted through holes and soldered |

| Component size | Small, compact | Large, for heavy components |

| Mechanical stability | Low | High |

| Production speed | High, automated | Low, manual/semi-automated |

| Repair | More difficult | Easier |

| Typical applications | Smartphones, computers, IoT devices | Industrial devices, power circuits |

When to Use SMT or THT

- Small, lightweight devices: SMT (smartphones, tablets, IoT devices)

- High vibration or mechanical stress environments: THT (industrial controllers, automotive electronics, power circuits)

- Prototypes and test circuits: THT, for easy replacement and testing

- High-frequency circuits: SMT, for short traces and low capacitance

- Mixed designs: SMT for signal components, THT for power components, combining the benefits of both

Hybrid SMT/THT

Many modern PCBs use hybrid assembly, mounting small signal components with SMT and large or heavy connectors with THT. This achieves a balance of high performance, mechanical stability, and production flexibility.

Conclusion

SMT and THT are fundamental PCB assembly techniques. SMT excels in compactness, fast automated production, and is ideal for modern consumer and IoT devices. THT offers mechanical stability, high reliability, and easy repair, especially in industrial and high-power applications. Choosing the right method based on application, production volume, and mechanical requirements ensures cost-efficient, reliable, and durable electronics. Using both methods in hybrid designs combines the advantages of SMT and THT for optimal performance. Furthermore, ongoing advancements in manufacturing technologies continue to improve both methods, enhancing efficiency and design flexibility. Engineers increasingly adopt hybrid solutions to balance miniaturization with durability. As electronic devices evolve, understanding when and how to use SMT and THT remains crucial for achieving innovative and sustainable designs.

🔗 Get in touch with us :

Phone/WhatsApp: +41 76 212 8248

✉️ E-Mail: info@revantechnology.com

For detailed information about our services in electronics development & PCB design:

Revan Technology – Your partner for professional electronics and PCB development

Discover our recent work:

Revan Technology – Our Projects