Gerber File

A Gerber file is a file that contains all the technical information needed to manufacture a printed circuit board (PCB).

It ensures that traces, holes, pads, masks, and markings from the PCB design are correctly transmitted to the manufacturer.

In short:

A Gerber file is a set of drawings that describes how a PCB should be produced.

What is a Gerber File Used For?

After the PCB design is finished, the manufacturer cannot directly produce the board from the design.

The reason: a PCB consists of multiple layers – including copper layers, solder masks, markings, and holes.

The Gerber format defines these layers.

For each layer, a separate Gerber file is created. These files are usually sent to the manufacturer as a ZIP archive.

What Does a Gerber File Contain?

A typical collection of Gerber files for a PCB usually includes:

| File Extension | Content |

|---|---|

| .GTL | Top copper layer |

| .GBL | Bottom copper layer |

| .GTS | Top solder mask |

| .GBS | Bottom solder mask |

| .GTO | Top silkscreen (text, logo) |

| .GBO | Bottom silkscreen |

| .DRL | Drill data |

| .GML / .GM1 | Board outline / contour |

Only the combination of these files creates a complete manufacturing guide.

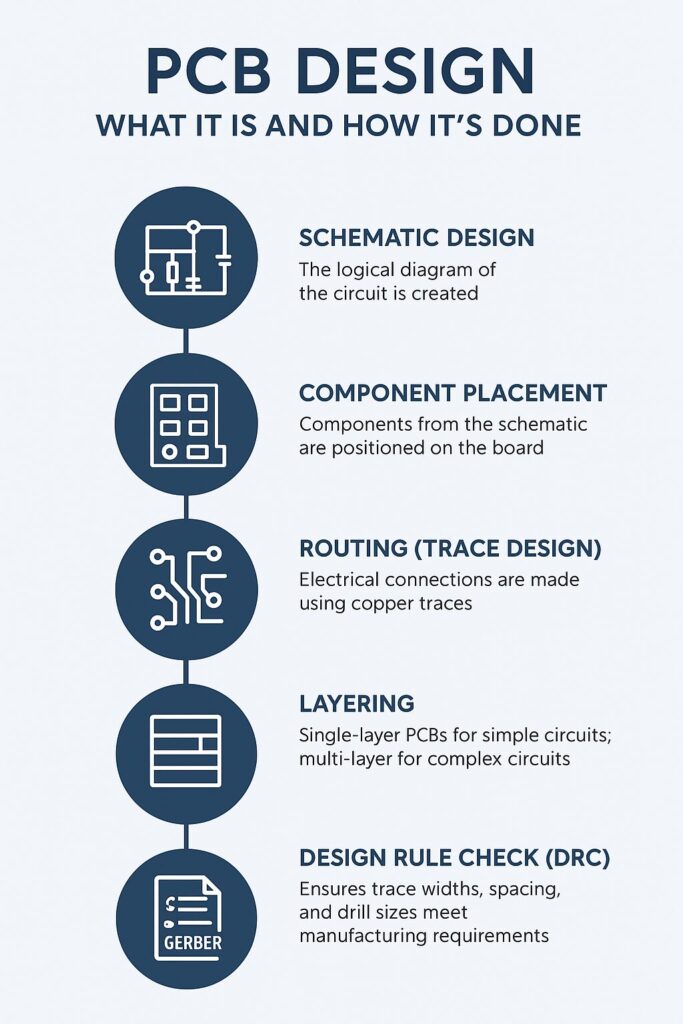

How to Create a Gerber File?

Gerber files are generated after completing the PCB design using the export function in the respective software.

This step is often called “Plot,” “Export,” or “Generate Gerber.”

Examples:

- Altium Designer: File → Fabrication Outputs → Gerber Files

- KiCad: File → Plot and select desired layers

- EasyEDA / Eagle: Generate Fabrication File (Gerber)

Additionally, a drill file is generated.

All files are collected in a folder, zipped, and sent to the manufacturer.

How to View Gerber Files?

Gerber files cannot be opened like normal image files.

To view them, you need a “Gerber Viewer” program.

Popular viewers:

- Gerbv

- ViewMate

- KiCad Gerber Viewer

- JLCPCB Online Viewer

This allows you to check before production whether everything is correct – for example, if a trace is missing or a hole is misplaced.

Gerber File Formats

There are two common formats:

- RS-274X (Extended Gerber)

The most widely used format today. Each file contains all necessary information for its layer. - Gerber X2

A newer format that also includes layer types, drill types, or material information – ideal for automated production lines.

Why Are Gerber Files Important?

Gerber is the standard language of PCB manufacturing.

Every PCB manufacturer can read and process this format.

Without Gerber files, the manufacturer would not know:

- Which lines should be made of copper

- Where holes need to be drilled

- Which areas should be covered with solder mask

- Where text or logos should be placed

Faulty or incomplete Gerber files can lead to production errors, short circuits, or scrap.

Therefore, a final Gerber check (DRC) should always be performed before sending the files.

Frequently Asked Questions

Are Gerber files only used for production?

Yes. Gerber files are exclusively for PCB manufacturing, not for simulation or testing.

Is it enough to just send the Gerber files to the manufacturer?

For PCB fabrication alone: yes.

If components are also to be assembled, a bill of materials (BOM) and pick-and-place data are also needed.

Who creates Gerber files?

The developer or PCB designer. The manufacturer uses them directly in production.

Conclusion

The Gerber file is the most important basis for PCB manufacturing.

Each layer of the PCB is described individually, and only the combination of all files results in a complete, producible layout.

Carefully prepared Gerber files ensure:

- Error-free manufacturing

- Faster turnaround times

- Lower costs

Faulty Gerber files, on the other hand, can cause:

- Scrap

- Production delays

- Possible malfunctions or complete failures of the circuit

Therefore, it is essential to generate, check, and, if necessary, correct Gerber data at the end of every PCB design process.

Thorough inspection before sending not only saves time and money but also prevents errors from appearing during manufacturing. Delivering clean Gerber files ensures smooth production and a reliable end product.

🔗 Get in touch with us :

Phone/WhatsApp: +41 76 212 8248

✉️ E-Mail: info@revantechnology.com

For detailed information about our services in electronics development & PCB design:

Revan Technology – Your partner for professional electronics and PCB development

Discover our recent work:

Revan Technology – Our Projects