Real-Time Data Collection for Monitoring and Optimizing Production Lines

In today’s manufacturing sector, competition is more intense than ever. Companies are turning to advanced technologies to monitor production lines efficiently, detect issues instantly, and optimize processes. Real-time data collection systems play a central role in this transformation.

Instant data collected from sensors, machines, and production management software allows businesses to monitor performance and make quick decisions. This increases efficiency, reduces downtime, and strengthens quality control processes.

Fundamentals of Real-Time Data Collection

Real-time data collection involves capturing and processing every action, sensor measurement, and machine output on the production line immediately. The goal is to observe production “live” and prevent issues before they occur.

For example, if a machine’s temperature rises suddenly, the system alerts operators, and the maintenance team intervenes. This prevents unplanned downtime.

Data Sources in Production Lines

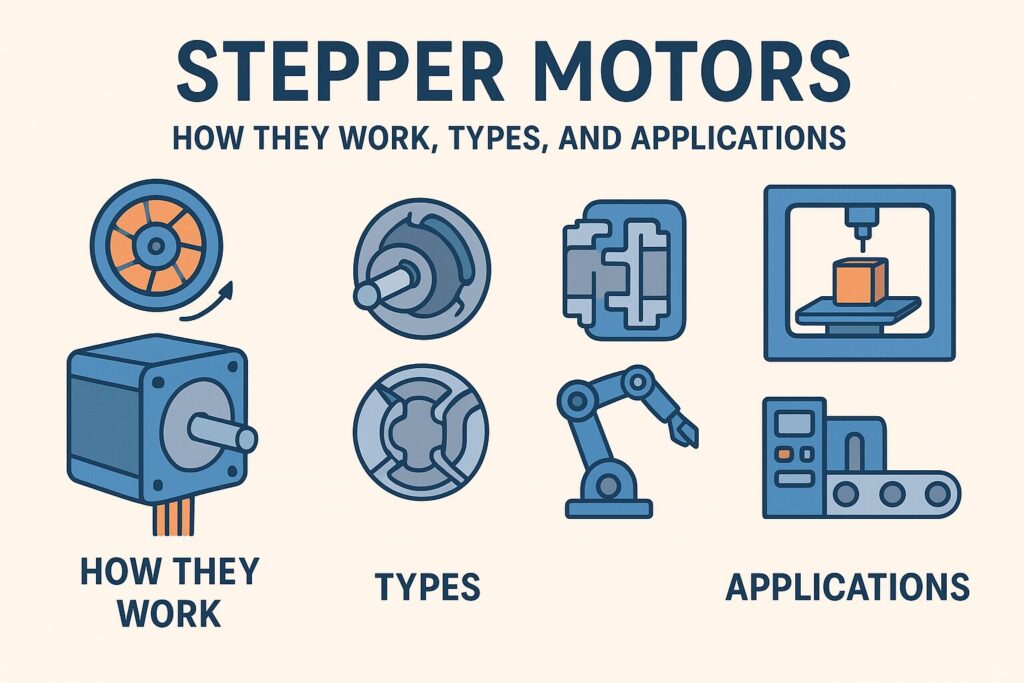

Real-time data collection systems draw from multiple sources:

- Sensors: Temperature, pressure, vibration, and humidity measurements

- PLC and SCADA Systems: Machine control data

- IoT Devices: Wireless data transfer and remote monitoring

- MES (Manufacturing Execution Systems): Production planning and work orders

Integrating these sources enables Industry 4.0-compliant production line management.

Operational Efficiency through Real-Time Monitoring

Real-time monitoring keeps every step of the production line under control. Machine performance, product quality, energy consumption, and workforce efficiency are measured instantly.

This approach reduces downtime, prevents production losses, and provides valuable data for continuous improvement.

Data Analytics and Optimization

Collected real-time data is not only for monitoring but also for optimization. Big data analytics and AI algorithms reveal bottlenecks and improvement opportunities in production processes.

For example, energy consumption data can identify the most efficient operating periods, reducing costs and supporting sustainability goals.

Proactive Maintenance and Fault Prevention

One of the most important benefits of real-time data collection is enabling predictive maintenance. Continuous monitoring of machine vibrations allows early detection of potential failures.

This prevents unplanned downtime, lowers maintenance costs, and extends equipment lifespan.

Quality Control and Product Traceability

Data collected on the production line strengthens quality control processes. Each product’s manufacturing parameters and machine history are recorded.

This ensures traceability and enables quick root cause analysis in case of customer complaints.

Competitive Advantage and Digital Transformation

Real-time data collection is not just an operational tool; it provides a competitive edge. Lower costs, higher quality, and shorter delivery times increase customer satisfaction.

Moreover, these systems are fundamental to digital transformation. At the heart of Industry 4.0 and smart factories lies real-time data management.

Conclusion

In summary, real-time data collection for monitoring and optimizing production lines is an essential requirement in modern manufacturing.

- Reduced Downtime through Instant Monitoring: Unexpected failures are prevented, ensuring production continuity. Operators can detect and act on issues immediately.

- Process Optimization via Data Analytics: Energy, time, and workforce are used efficiently, and bottlenecks are clearly managed.

- Lower Risk with Predictive Maintenance: Machine lifespan is extended, unplanned downtime decreases, and maintenance budgets are used efficiently.

- Improved Quality Control and Traceability: Every product’s production history is recorded, ensuring quick problem resolution and brand reliability.

- Strong Step Toward Digital Transformation: Industry 4.0-compliant smart factories are established, preparing companies for current and future competitive demands.

Real-time data collection applications not only increase speed and efficiency in daily operations but also provide long-term cost advantages, sustainability, and global competitiveness. Companies using these systems gain superiority not only in production lines but also in supply chain management and customer satisfaction.

Looking forward, AI-based analytics, machine learning, and IoT integration will further advance real-time data collection, enabling self-learning, adaptive, and low-error production systems.

In short, businesses that use real-time data effectively stay a step ahead in today’s competition and secure a solid place in the digital industries of the future.

🔗 Get in touch with us :

Phone/WhatsApp: +41 76 212 8248

✉️ E-Mail: info@revantechnology.com

For detailed information about our services in electronics development & PCB design:

Revan Technology – Your partner for professional electronics and PCB development

Discover our recent work:

Revan Technology – Our Projects